How To: Make an AC Arc Welder Using Parts from an Old Microwave, Part 1

In a previous article, I demonstrated an Arc Welder made using parts from old microwave ovens. Please enable JavaScript to watch this video.

Here is part 1 of 2 on how that arc welding machine was made, and how you could make one too! This is the first of two parts on building it, focusing on the modification of the transformers. Please enable JavaScript to watch this video.

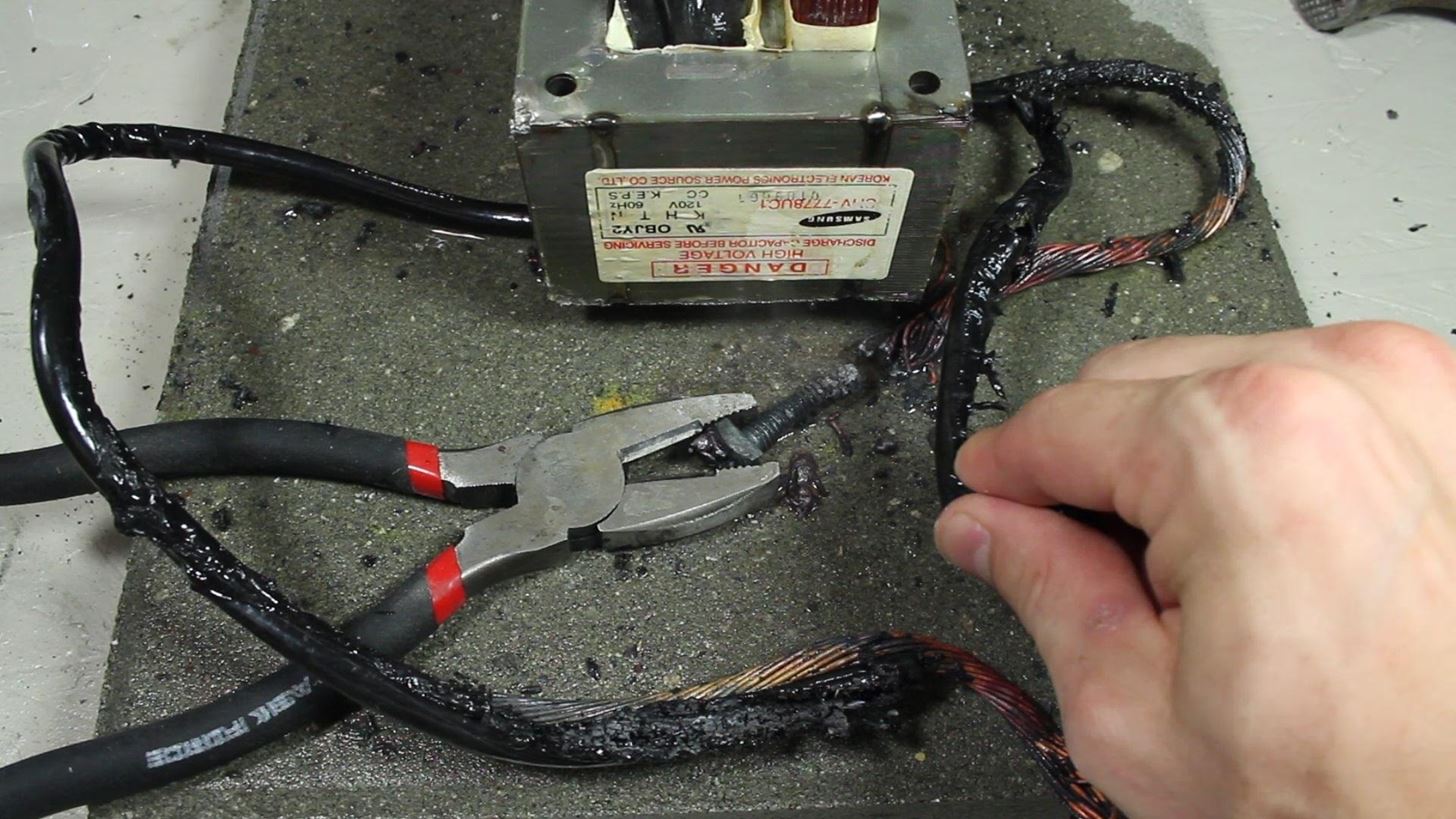

WARNING: Stick welding, and/or the modification of a Microwave Oven Transformer (M.O.T), can be very dangerous and presents risks of UV radiation, shock hazards, burns, fires, fumes and a multitude of other risks. This project should not be attempted without a thorough understanding of electricity, adult supervision and adequate training. Misuse, or careless use, of tools or projects may result in serious injury and/or death. Use of this content is at your own risk. In a previous project, I melted the lead wires on my first metal melter. But the transformer core was still in great condition, so I re-used it to make an AC stick welder!The arc welder made sparks fly, but in the end, it wasn't enough power to make the metal stick, and the pieces of work would break apart with very little effort.If I tried pumping more power into the welder, the wires would overheat and melt.So to address this challenge, we'll be using 2 MOTs (Microwave Oven Transformers), because more transformers means more power! Preparing the MOTs for a new secondary is exactly the same as the first few steps we took in the Metal Melter project. As it's a little redundant, I won't spend much time on the step-by-step instructions for that, but if you haven't seen it yet, you can check out the video, or reference my previous article. To make life a lot easier, you're going to need to build a little jig for winding your secondary. It's unlikely you'll get all the required turns of wire in such a tight space without one.To make this jig, I used a piece of scrap wood and cut it so that it was as wide as the center of the transformer, and just a little shorter than the top. The length was cut so that it overhung about 1/2" from the ends.I screwed wood panels on the top and bottom to guide the wires and keep them in place, then folded a piece of paper so that it fit in the groove.Once mounted in a bench vice for leverage, the cable can be wound on.For this project, try to round up around 50'of 8 AWG stranded copper cable from a local hardware store. You could probably save some money by scavenging for free wire, but I decided to look at the "end of coil" section at the hardware store, and was able to negotiate a deal for half price on the cable, so the 50' only cost me about $17.These modified MOTs will need a new secondary that is 18 turns of the 8 AWG cable, and both MOTs will be tied together in series. I also found I needed to run the system on 240 volts AC to get the power output for good welding. My goal was 30+ volts AC with a variable amperage from 0-120+ Amps.In practical terms, this means you need to wind the coil on the form so that you end up with 6 cable lengths high, and 3 cable lengths wide. Oh yeah, and it all needs to be able to fit back in the transformer, so wind it tight!The first layer isn't too bad, but winding the second layer, and third get progressively more difficult, and may seem near impossible.Once you get the 18 turns of wire to fit in the groove, you can fold the paper over, and tape it together to help the coil hold together.Here's the tricky part .. get it off the jig without letting it unravel!The top and bottom panels can be removed, and the block pushed out from the center of the coil. I used electrical tape to make sure the coils stayed tight. Putting the secondary coil in the transformer is a very tight fit.I had the best success by using a set of clamps to squeeze the sides of the coil in, while I used a rubber hammer to gently tap the coil down.When it's in, the coil had better fit below the top edge of the transformer, otherwise you won't be able to get the top back on.Securing the top on is the same as in the Metal Melter project as well. Basically, use 2 part epoxy glue to cover the entire top surface, then replace the iron lid and press it together tightly in clamps or a large vice.It's extremely important to have a lot of pressure on the joint while the epoxy is setting. I let mine set for about 24 hours.The modified transformer is complete! The secondary coil is so tight in there, that any vibrations from the 60Hz mains power will be kept to a minimum. When both transformers are modified in the exact same way, we've basically got what we need for welding. All that's left is to clean it up a bit and make it more useful and presentable. By the way, these two exposed wires from the secondaries will become our ground clip and stinger.Well, there they are! The basic makings of an AC stick welder. From this point, it isn't difficult to finish the system up into a nice little hobby welder. Watch how to do that in Part 2. Please enable JavaScript to watch this video.

If you haven't see the video yet, it's not too late. Watch it here!If you like this project perhaps you'll like some of my others. Check them out at thekingofrandom.com.

Mobile Leer en español How to use Google search to find your lost Android phone. Run a search for your Android phone via Google it'll pinpoint the phone's location on a map.

Get started with Google Photos - Android - Google Photos Help

You may be paying $80 a month for your wireless bill, but that doesn't stop Verizon from selling your personal data to advertisers. Who you call, your travel patterns, the websites you visit, which mobile apps you use, whether you're a pet owner-all that and more is for sale through its new program, called Precision Market Insights.

iOS Tips: How to Stop Sharing Your Location in iMessage | The

A Return to Glory? HTC Releases the U12+ with 4 Cameras, Edge

Discover what's draining your iPhone battery and what you can do about it. the more likely they are to run out of juice when we need them most. You do not need to close apps to save power

Closing All Apps to Save Your Battery Only Makes - WIRED

An introduction to the Speed Dial feature on BlackBerry® smartphones. Speed dial is a handy function that does what the name implies: it quickly dials a phone number. With the push of one or two buttons (depending on your model of BlackBerry smartphone) your device is making an outgoing call.

Speed dial contacts - BlackBerry Forums at CrackBerry.com

Groups allied to the opposition say that the killings, brutal beatings and rapes against them are part of a wider campaign of violence. Protesters have rejected the Transitional Military Council's plan for an election in nine months, saying it won't be free or fair and have called for civil disobedience to start next week.

Apple Watch Series 3 reviews are out and here's what people

How To: Mark exact spots on a Firefox webpage with the Dog Ears extension How To: Train a pet cockatiel to do tricks How To: Say the names of animals in Japanese How To: Identify the common crow when bird watching

How to Translate languages using Google Firefox Extension

It feels strange to be walking through an open field in a small village in the English countryside. There's no one else around — just the four of us: me, my husband, my 12-year-old son, and my adult niece.

Turn a Vacation into a Treasure Hunt with Just Your Phone

How To: Install the Leaked Galaxy S8 Android Oreo Update Now How To: Unroot & Restore a Galaxy S5 Back to Stock How To: Install the Leaked Lollipop Firmware on Your Galaxy Note 3 (Update: Now for AT&T) News: Android 4.4.2 KitKat Is Finally Here for the Samsung Galaxy Note 2

Android 5.0 Lollipop leaked for Sprint Galaxy S5

Candy Crush Saga Hard Levels: Level Tips and strategies to get past this challenging level. Best Methods for Candy Crush Level Skip [New] candy crush now How do I clear Candy Crush Level - Without The Sarcasm A very funny blog post about Candy Crush Level 70. This will only be funny if you've been there. See more

Omgå Candy Crush Saga's Waiting Period for at få nye liv og

How to Use Siri on an iPhone. This wikiHow teaches you how to set up and use the iPhone's personal assistant, Siri. Make sure your iPhone supports Siri. Any iPhone, from the iPhone 4S to the most recent model, supports Siri.

Siri Commands List: How to Use Siri for iPhone X, iPad: Siri

Although widgets were finally introduced in iOS 8, they weren't exactly the widgets we were expecting, i.e., the ones seen on Android home screens. Don't get me wrong, they're still very useful in the Notification Center, since they can be accessed with a quick pull-down from any screen, but there are some widgets that would work better right on the home screen.

The Easiest Way to Add Widgets to the Today View on Your

How-To APPL with a tutorial on how to close apps completely in iOS 12. Welcome to the How-To APPL Youtube Channel! Focused on helping you learn, fix, and embrace your Apple products, such as, your

Force Close Apps in iOS 12.3.1/iOS 12 on iPhone and iPad Pro

Then I will construct the entire slide mechanism assembly and fasten it to a 1" pipe. Generally, the concept behind the slide mechanism is similar to the previous machine made of MDF and aluminum angles. With the pipe CNC machine, I use pipe floor mounts to flank the pipe with two similar bearing trucks between the floor mounts and the pipe.

How to Make a slide projector using common materials « TVs

0 comments:

Post a Comment